우수연구성과

Chung-Ang University Researchers Develop Smart Portable Sensing System for Monitoring Precast Struct

RESEARCH NEWS STORY

Chung-Ang University Researchers Develop

Smart Portable Sensing System for Monitoring Precast Structures During Delivery

The multimetric portable system uses an IoT sensor to simultaneously

measure strain and acceleration of the structures real-time during delivery.

Precast

concrete structures (PCS) reduce workforce dependency and construction time.

However, they are subjected to vibrations and strain during transport from

their manufacturing site to the construction site. Effective quality control

measures require continuous logging of vibration and strain measurement during

the delivery, an essential feature that is missing in current systems. To this

end, researchers have now developed a novel portable sensing system that can

monitor strain and acceleration to enable efficient PCS delivery.

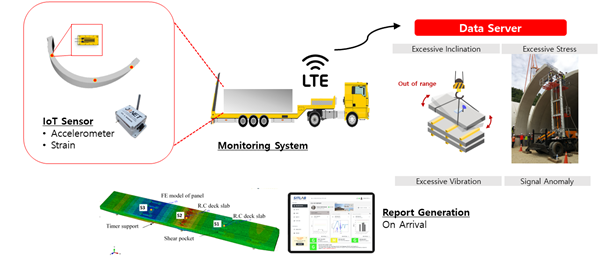

Image Title: A smart portable delivery monitoring

system for real time tracking of precast structures.

Image Caption: In a recent study, Chung-Ang

University researchers develop a novel IoT-based sensing system that can detect

vibrations and deformations in precast structures during delivery and reports

events during transportation that could potentially impact their quality.

Image Credit: Dr. Jongwoong Park from Chung-Ang

University, Korea

License Type: Original Content

Usage Restrictions: Cannot be reused without permission

Precast structures are like giant lego blocks made of concrete that are

manufactured in a factory to enable seamless construction at a building site.

Modern urban construction projects rely heavily on precast concrete structures

(PCS) for a quality and timely completion. PCS are manufactured in a controlled

environment that ensures the highest quality. However, during delivery to the

construction site, they can be damaged by shocks and imbalanced loads during

lifting that make them unstable. Sometimes, the damage can go unnoticed during on-site

construction. However, this can lead to a potentially dangerous situation over

time. Moreover, high replacement costs and long downtimes make remedial

measures ineffective. “We have seen multiple instances of damage during

transportation; we are, therefore, working on a solution to address this issue

using an IoT sensing system to monitor PCS during delivery,” notes

Associate Professor Jongwoong Park from Chung-Ang University, who has been

actively researching on Internet of Things (IoT) sensor systems.

To this end, Dr. Park and his colleagues at Chung-Ang University recently developed

a smart sensing system to monitor PCS during transportation in real time. The

system integrates IoT sensors that detect vibrations and deformations during

movement. In a recent article published in Automation in Construction, the researchers detailed the development of this specialized IoT-based

sensing system. The paper was made available online on 16 November 2022 and was

published in Volume 145 of the journal in 01 January 2023.

“We have enhanced the portability of the sensing system and have created

a method for monitoring the deformation of precast structures during lifting

and transportation. This system can help prevent any damage that may occur

during transportation, ensuring a safe and sound delivery,” explains Dr.

Park.

The novel portable wireless sensing system is capable of real-time

recording of acceleration and strain measurement during transport. Moreover,

the system generates a safety assessment report for PCS that adjusts initial

strain offset and calculates the absolute strain. To demonstrate the

capabilities of their smart system, the researchers further conducted a field

test constituting an 80-minute delivery of a 12-meters long precast concrete

beam and evaluated its condition by measuring the acceleration, tilts, and

strain of the structure in real time. Further, the researchers processed and

analyzed the measured data and conducted a safety assessment.

Interestingly, while the results indicate that the sensing system was

effective for precast monitoring, the system does not allow for timely

decisions by supporting real-time data management. In this regard, future

research is required towards developing a cloud-based monitoring system that

can alert users of anomalies in real time.

Nevertheless, the novel development by the team has potential for immediate

smart delivery monitoring applications in construction projects. “With our IoT-based precast monitoring

system, we can ensure the long-term safety and reliability of precast

structures. This technology will prevent such issues from occurring, making our

buildings safer and more efficient in the future,” concludes an optimistic

Dr. Park.

Reference

|

Authors

Title of original paper

Journal |

Sadia Umer Khayam, Jongbin Won, Junsik Shin,

Junyoung Park, Jong-Woong Park

Monitoring Precast Structures During

Transportation Using A Portable Sensing System

|

|

|

|

|

DOI

Affiliations |

10.1016/j.autcon.2022.104639

Department of Civil and Environmental

Engineering, Urban Design and Studies, Chung-Ang University

|

Your Press Release Source

Chung-Ang University

About Chung-Ang University

Chung-Ang University is a private

comprehensive research university located in Seoul, South Korea. It was started

as a kindergarten in 1916 and attained university status in 1953. It is fully

accredited by the Ministry of Education of Korea. Chung-Ang University conducts

research activities under the slogan of “Justice and Truth.” Its new vision for

completing 100 years is “The Global Creative Leader.” Chung-Ang University

offers undergraduate, postgraduate, and doctoral programs, which encompass a

law school, management program, and medical school; it has 16 undergraduate and

graduate schools each. Chung-Ang University’s culture and arts programs are

considered the best in Korea.

Website: https://neweng.cau.ac.kr/index.do

About Associate Professor Jongwoong

Park

Jongwoong Park is an Associate Professor at the

Department of Civil and Environmental Engineering at Chung-Ang University in

Korea since 2021, having previously served as an Assistant Professor at the

same institute from 2017. Dr. Park earned his Ph.D. and M.S. degrees from

KAIST, Korea in structural health monitoring using IoT and computer vision. He

has published over 40 research papers and holds 15 patents related to

structural health monitoring. His research interests include IoT, deep

learning, sensor development, and cloud computing.

CAU Scholar's

Space: https://scholarworks.bwise.kr/cau/researcher-profile?ep=1007

About Sadia Umer Khayam

Sadia Umer Khayam is currently enrolled in a Ph.D. degree in civil

& Environmental engineering, Chung-Ang University, South Korea. Her

research interests are finite element modeling, structural health monitoring.